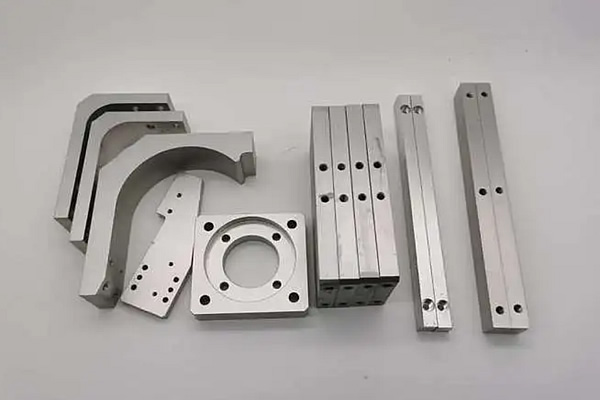

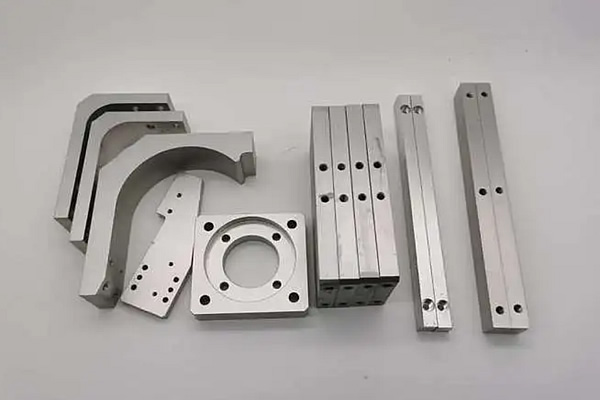

Machining Before the product processing,it is necessary to know the testing standards of the machined products,so that we can know whether the product specifications meet the customer requirements.What is the testing standard for machining?

1.Divide the number and copy the number.After each minute is completed,first copy the number of work coordinates.After clearing,check the interval between the center and the two sides to ensure that the points are correct.

2.Select the knife,load the knife,set the knife,and copy the number of Z-axis coordinates.Select the appropriate tool according to the programming list.Before installing the knife,clean the blade and the nozzle thoroughly.After installing the knife,use the calibration meter to see if the knife has no yaw.After checking the number of knives,you should look at it from the beginning to prevent the wrong knives,and the wrong number will bring significant losses to the company.

3.Transfer program,start processing:use single block performance before the lower knife,adjust the transmission speed and feed speed to the slowest speed,slow down the knife,watch the machine tool show Z-axis margin,check whether there is abnormality,if abnormal Press the Pause button immediately to find the cause of the abnormal processing.After everything is normal,adjust to the appropriate speed to start processing.

4.During the processing,it is necessary to pay attention to whether the processing is abnormal or not,the knife has no wear,and the tool wear is severe,and the grinding is suspended to ensure normal processing.

Machining requires the necessary testing of the products according to the above four testing standards,so that the mechanical processing products can meet the requirements of customers,in order to better improve the quality of mechanical processing products.

Phone: +86 13416744140

Phone: +86 13416744140  Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China

Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China