What Is Machined Casting?

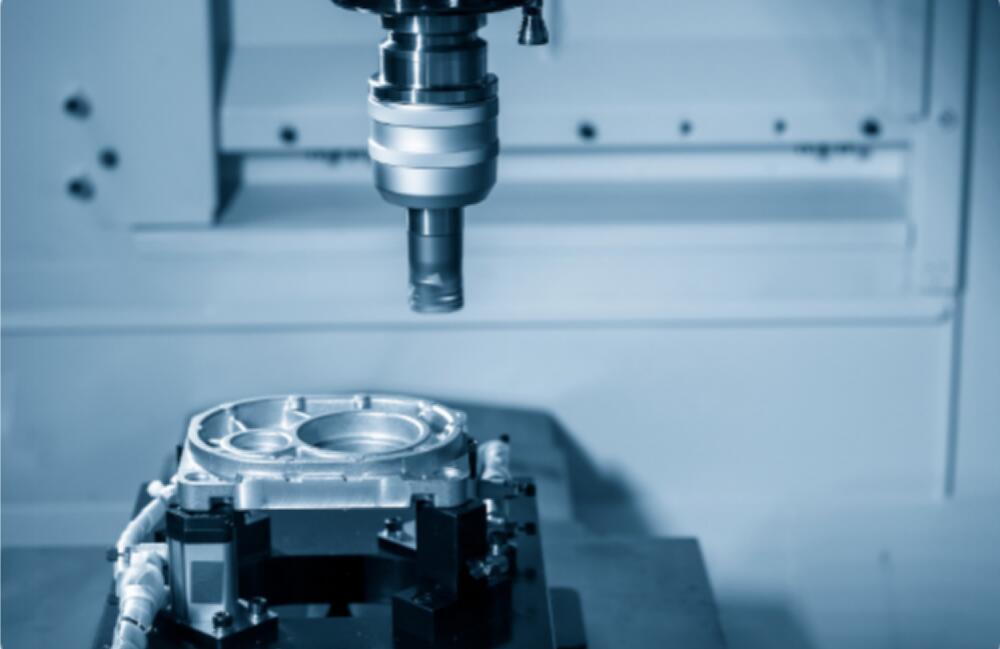

Machined casting is a part that was first cast into a semi-finished product, then finished with precision CNC machining.

You can produce the initial castings using one of several casting methods, such as die casting, investment casting, or sand casting. However, each of these casting methods tends to have its own drawbacks, like a rough surface finish or the inability to make certain design features.

CNC machining helps improve product quality and adds missing design elements. You can use one or more machining processes — like CNC milling, turning, drilling, sawing, or a less conventional machining method — to help create premium finished products.

304 |

The most widely used austenite steel, may be referred to as A2 stainless. |

304L |

This grade has slightly lower mechanical properties than the standard 304 grade, but is still widely used in casting for its versatility |

316 |

The second most common austenite steel, also referred to as A4 stainless. SS316 primarily serves to enhance resistance to corrosion. |

316L |

Lower carbon content than 316 stainless steel, which reduces the sensitization effect caused by the high temperatures involved in welding. Besides, it shows better resistance to stress-corrosion cracking. |

17-4 PH |

Most common precipitation-hardening martensitic stainless steel, which uses about 17% chromium and 4% nickel. |

2205 Duplex |

Used for its good mechanical properties and excellent corrosion resistance properties. |

The Benefits of Machining Castings

The machining of castings has two primary benefits:

1.Adding features and removing unwanted as-cast material.

2.Improving precision and surface finish.

To better understand why these benefits are so important, let's explore the applications relevant to each one.

1.Modifying As-Cast Parts

Parts that technicians have only just removed from their casting mold are considered “as-cast.” The manufacturer hasn't subjected them to machining, sandblasting, or another finishing process.

Modifying as-cast parts is the addition of features that you cannot effectively produce using casting. For example, you can't produce the curved fins on a turbine using a permanent mold because you cannot separate the mold halves after the casting material hardens.

And while you could use a technique like investment casting to address casting designs where you cannot remove the mold halves, many other casting challenges could make machining the preferred solution. For example, holes, grooves, and threads are often much higher quality when produced by CNC machining.

3.Improving Finished Quality

Even if a casting does not need additional machined features and you can easily remove the gating, precision CNC machining is an essential step for top-quality parts.

Casting methods like die casting produce a superior surface finish relative to other casting methods, so they may only need minor machining touchups to remove parting lines. But machining castings becomes essential for parts produced by sand casting and investment casting if they must have a smooth surface finish.

The other essential reason for machining castings is to improve accuracy and precision on parts with strict tolerance limits. Modern CNC machines can achieve a much higher degree of precision than casting.

Fabricators that need to produce a large volume of identical parts can take advantage of casting to save cost, then use CNC machining to meet tolerance requirements. But to do this, designers must account for machining allowances in the casting stage.

Adding Machining Allowances to Your Designs

Regarding machined castings, designers must incorporate machining allowances into the mold design so that as-cast parts have enough material for precision machining.

For example, imagine your finished part has a small protrusion with tight tolerances. If the mold design has a feature the same size as the protrusion, any shrinkage or porosity will make the feature smaller than it was supposed to be. If you need any machining to improve the surface finish or refine the shape of the protrusion, machinists would be forced to remove even more material or risk leaving the part rough and unfinished.

Adding machining allowances to your part design slightly increases the size of any as-cast parts or part features that the manufacturer will finish with CNC machining. These allowances help fabricators consistently meet tolerance requirements with fewer rejected parts while significantly reducing machining times. Below is the general tolerance of investment castings you may consider when designing your products.

ISO8062(GB/T6414) CT5-CT6 |

|||||

Linear Dimensional Tolerance (mm) |

|||||

| > | ≤ | CT5 | CT6 | ||

| 0 | 10 | 0.36 | ±0.18 | 0.52 | ±0.26 |

| 10 | 16 | 0.38 | ±0.19 | 0.54 | ±0.27 |

| 16 | 25 | 0.42 | ±0.21 | 0.58 | ±0.29 |

| 25 | 40 | 0.46 | ±0.23 | 0.64 | ±0.32 |

| 40 | 63 | 0.5 | ±0.25 | 0.7 | ±0.35 |

| 63 | 100 | 0.56 | ±0.28 | 0.78 | ±0.39 |

| 100 | 160 | 0.62 | ±0.31 | 0.88 | ±0.44 |

| 160 | 250 | 0.7 | ±0.35 | 1 | ±0.5 |

| 250 | 400 | 0.78 | ±0.39 | 1.1 | ±0.55 |

| 400 | 630 | 0.9 | ±0.45 | 1.2 | ±0.6 |

Producing Machined Castings with MXG Mechanical

At MXG Mechanical, we regularly produce a wide range of top-quality machined castings. Our expert team has the know-how to optimize production for maximum cost savings and the fastest possible lead times.

At our service locations in China, we offer our customers premium casting and CNC machining services with convenient shipping to anywhere in the world. Choose MXG for your next machined casting project!

Phone: +86 13416744140

Phone: +86 13416744140  Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China

Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China